We can provide various solutions of deburring machine. Deburring by soft uniflap wheels, wire brushing, wire wheels, carbide cutting tools with robots automation and many more, depending on the application requirements.

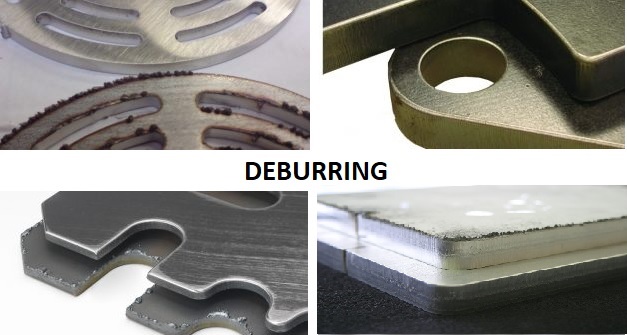

What is a burr? A burr is a small piece of material that remains attached to the edge of the work piece, or the raised edge of the surface. Burrs are commonly created by most machining operations, such as drilling, milling, turning, stamping, laser cutting, punching, plasma cut, shearing, or engraving. Casting parts also create burrs as well. Quality of part is affected by burrs and it is necessary to remove the burrs from the part. We call this removal process, DEBURRING!

There are many deburring processes such as manual deburring, wire brushing, media blasting, mass-finishing, grinding, electrochemical deburring, abrasive wheel deburring and many more. In our current working environment, manual deburring process is largely present. Companies are searching for better ways to reduce the dependency of manual deburring. We have the solution, our deburring machines!

Our deburring machine is targeted to improve the cycle time and increase consistency quality of part. In addition, companies will benefit from consistent parts' output, reduce labour dependency. While worker's skills will be upgraded to learn to operate the machines, they will be equipped with the knowledge through training. Our deburring machines are compliance with the global manufacturing practices. We save your time!

Advantages

- Eliminates health hazards of manual deburring

- Noise - Permanent Hearing Impairment

- Air quality - Lung disorders from Fine Aluminum dust

- Vibrations - Continuous exposure to vibrations causes nerve damage

- Consistent Quality of deburring

- Less Manpower

- Upgrade workers' skills

- Compliance with Global Manufacturing Practices